The early cat owners found that cats have the habit of covering their excrements with sands by themselves. So they took the outdoor sands to home for cats to use, and then clear out the used sand regularly. Such practice lasted for a long time.Until people discovered the bentonite (or clay) with clumping characteristic.They also found that it could eliminate cat urine effectively and easy to clean. So bentonite litter led cat litter market for a long time.、

Manufacturing processes

The production of bentonite cat litter mainly consists of the following processes,rough selection,drying,grinding,granulating, drying,screening,and packaging.

- Rough selection First.

The original bentonite has a water content of about 20%. And the factory need to pick out the stones with a diameter of more than 20 cm.

- Drying.

The selected bentonite need to be transported to the drying yard, and dry its moisture to 13-14% through natural drying.

- Grinding.

The workers grind the dried bentonite to powders (about 200 mesh) with a Raymond machine.

- Granulation.

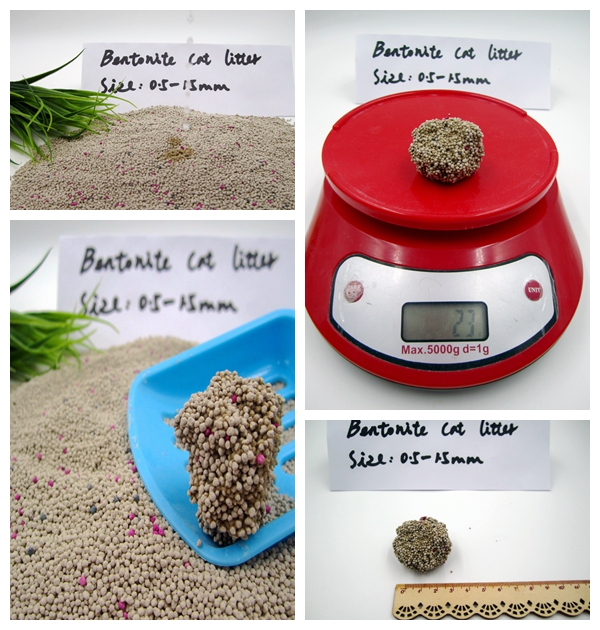

Put the powders in a circular granulation tray, and use the water spray nozzle to make the bentonite powders into a spherical shape with a diameter of 0.5-4.5MM, with a water content of about 15%-20% .

- Drying.

Load the bentonite particles in the drying cylinder with a conveyor belt and dried to a moisture content of 4%-5%.

- Screening and packaging.

The dried bentonite particles are transported to the vibrating screen by a conveyor belt, and different sizes of particles will be screened out.Then packed and sold.

Advantages for bentonite cat litter

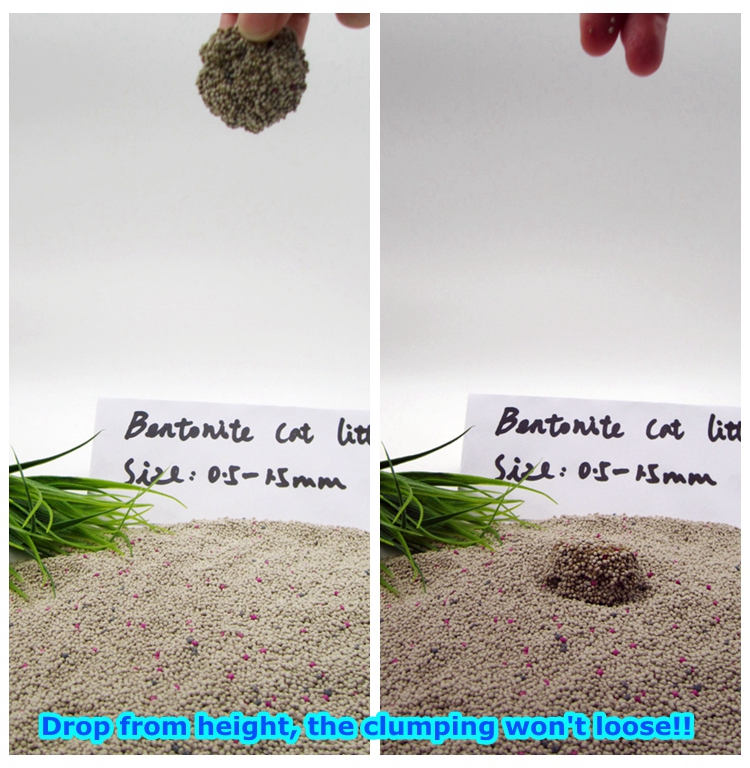

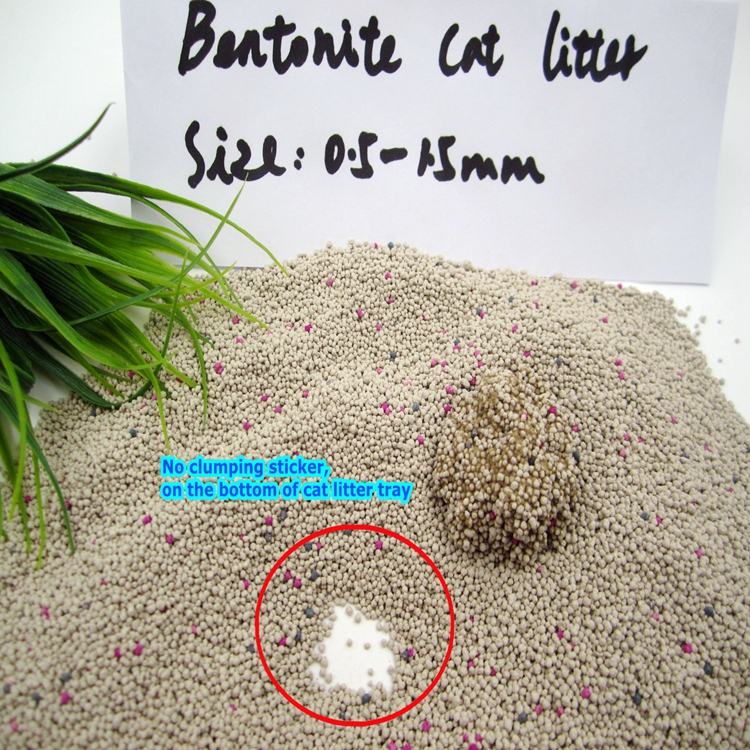

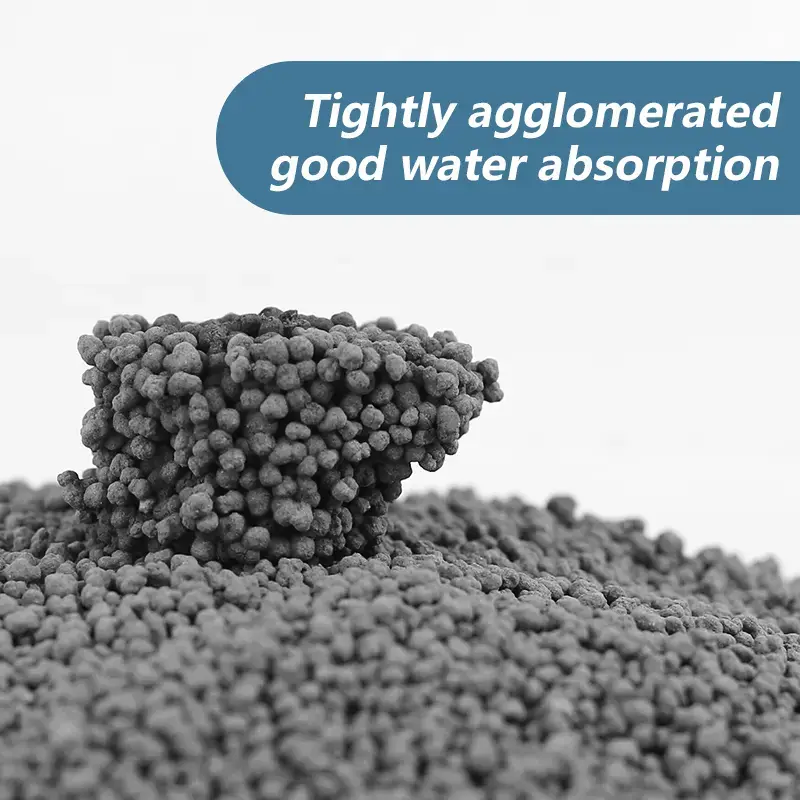

It's a kind of clumping cat litter made by 100% natural bentonite. It's with superior water absorptivity, deodorizing capacity and adhesive property than the traditional clay. It's non-toxic, environment-friendly and economical cat litter nowadays.